Description

Features:

Closed impeller design.

- Operate easily ,simple maintenance.

- Flexible couplings designed specially to attend to heavy duty and high efficiency.

- Double bearings can run in balance and extend working period.

- This model has a long working history, it is believable and reliable.

- Temperature resistance to 300°C.

- Optional accessories: double mechanical seals.

Application:

- Aircon systems of high-rise or textile seals.

- Agricultural irrigation used.

- Water supply used.

- Civil engineering used.

- Firefighting water supply.

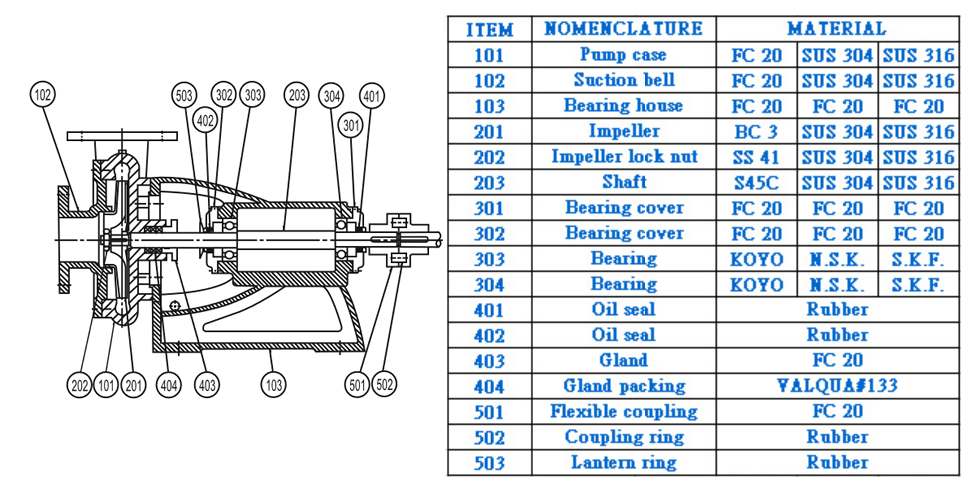

Construction:

- Pump case:Entrance is the same direction with shaft. Discharge direction is vertical and up. There’s an infusion hole out of the stuffing box in order to infuse water to protect shaft and gland packing. Inside the sluffing box is gland packing or mechanical seal.

- Bearing house There’re 2-3 ball bearings inside it. Using grease or oil to lubricate it. Fluid valve can check the situation of lubrication oil or grease inside.

- Impeller: AII impellers are dynamic and static balanced. “balance-holes”are drilled on the impeller to balance the thrust from the shaft and reduce vibration.

- Rotation:Clockwise rotation when view from the driver end.

- Transmission:Belt, motor ,or engine driven.

Pump Range:

- Pump material: cast iron Clean liquids: 0°C-60°C water ,PH 6~8.

- Pump material: stainless Corrosive liquids: 0°C~120°C acid/alkali liquids ,PH 1~ 12.

Please inform us that if using the special liquids

(ex: specific weight, consistence, temperature or other features.) - Hot kerosine pump:Temperature resistance to 300°C

- Chemical pump: Applicate to corrosive and volatile liquids. To ensure the safely,you can additionally take explosion-proof motors.

- Transmission:Belt, motor ,or engine driven.